• High performing relational database system

• Full support of all HAZOP types (Process, Facility, Design, Planning, HAZOP-MSR, PHA)

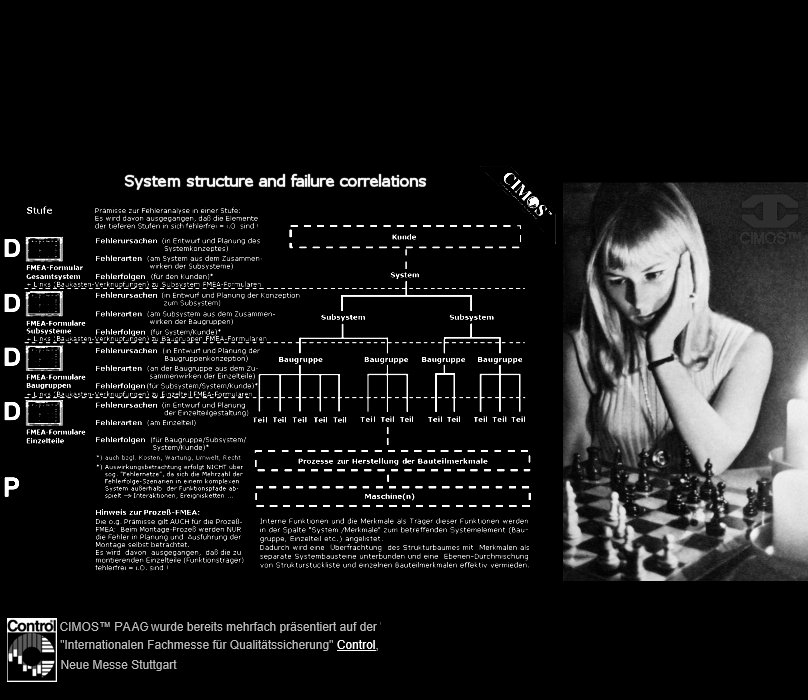

• Modular structure based on process step / function related resources

• Tree chart representing current system and/or process structure

• User defined standard text catalogues and checklists for data entry

• Copy function for complex HAZOP system tree structures (product / process variants)

• Unlimited text volume in HAZOP forms, internal entries for comments

• Definition of individual PN (Priority Number) evaluation factors, SIL evaluations also available

• Prioritization of actions according to cost/effect levels

• HAZOP form printout acc. to QS 9000 / IEC 61882:2017 or user defined

• Hazard tree chart (cause/effect diagrams) and risk matrices as additional print formats

• HAZOP version manager with release status und automatic filing (archives)

• Time limits supervision and full "Action Priorities"(AP) support acc. to the latest standards

• Application controlled eMail dispatch of corrective action reminders

• Risk Priority Number (Occurence, Severence, Detection) ranking list

• Pareto chart for risk evaluation

• 'Executive report' for consolidated management information

• Text retrieval and search functions for detection of analogies in former studies

• Passwords for user specific functional application restrictions

• Control Plan acc. to ISO TS, consistently linked to the HAZOP data

• Interface for 3D viewer applications (CAD, BIM)

• Windows™ Excel™ utility for data import from external HAZOP and/or PHA spreadsheets

• HAZOP form content comparison to show the modifications between different version releases

• Floating server license: Price as single user, access from any network PC possible

• Self-sufficient, no third-party tools or external database licenses required